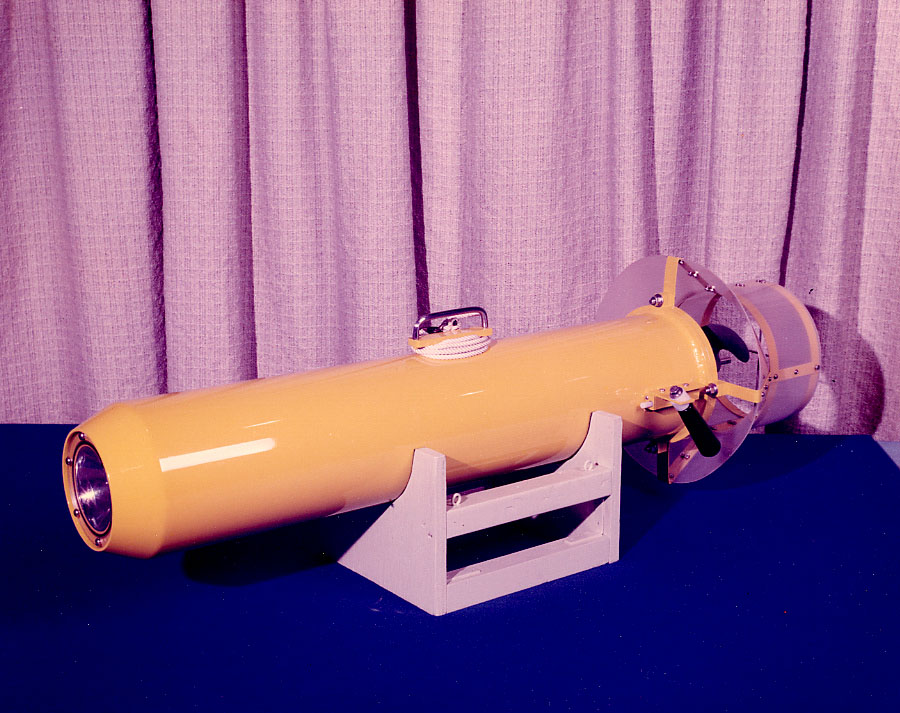

Diver Propulsion Vehicle

A Diver Propulsion Vehicle (DPV) is a device that tows a scuba diver at

speeds of up to 2.5 mph underwater or on the surface. It is a small, torpedo shaped,

cylinder approximately 8 inches in diameter and 36 inches long. The diver holds onto two

handles at the back which contain switches for the motor and underwater headlight. When in

use the diver's body streams out horizontally behind and above the DPV allowing the

propeller wash to flow under the divers body.

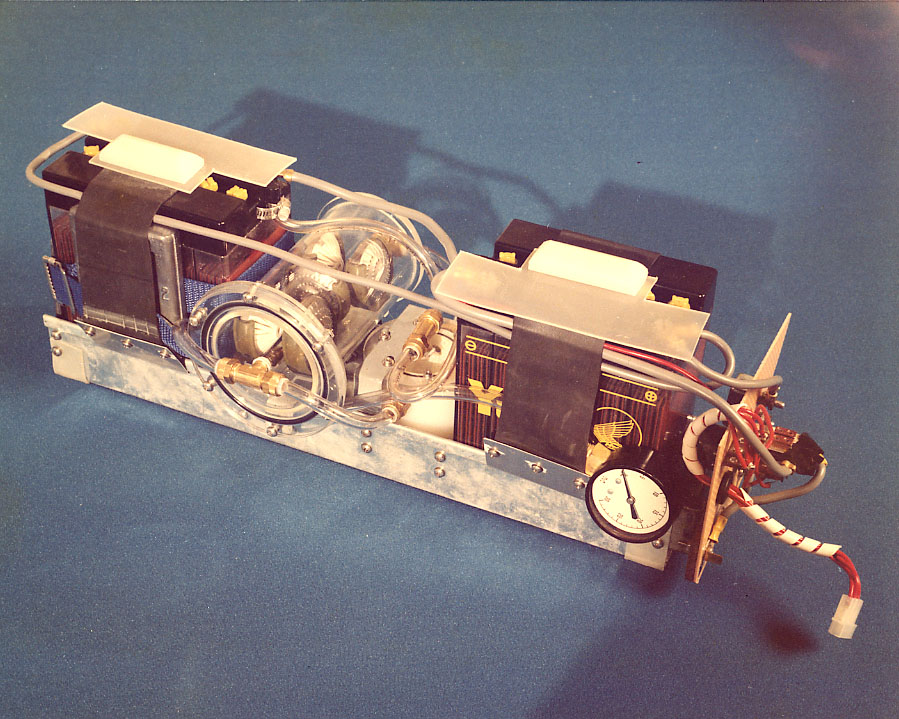

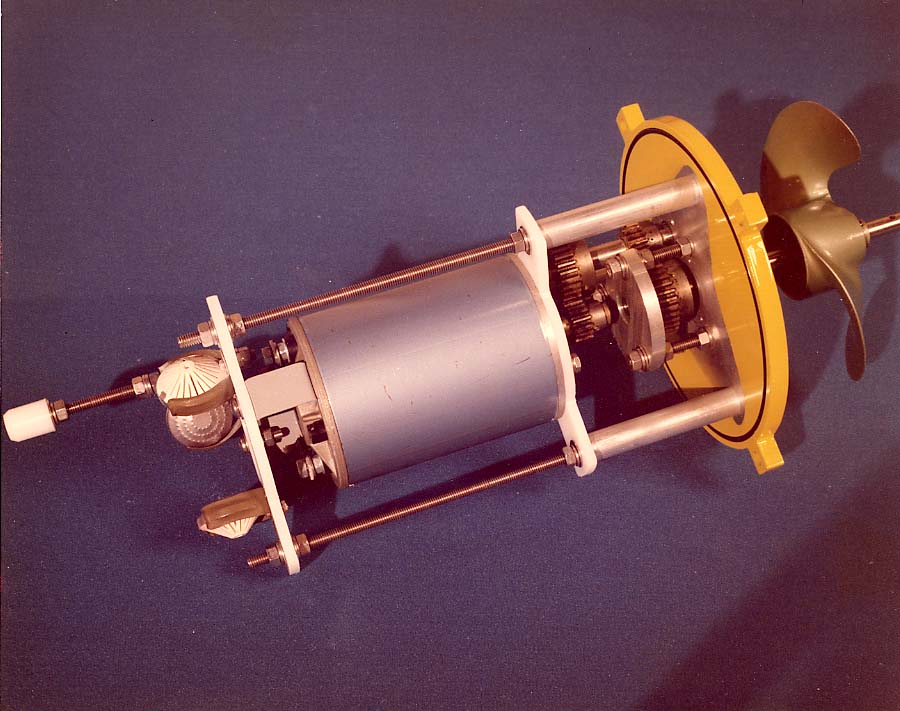

Propulsion is generated by a 1/3 HP permanent magnet DC motor running at 3600 RPM. The

electrical power comes from two 12 volt 14 amp hour batteries, wired in parallel, which

provide 12 volts at 28 amps. The motor shaft is stepped down through a custom 4 to 1

geared speed reducer to a shaft speed of 900 RPM which drives the two bladed propeller

directly. The battery system also includes a sealed chamber for palladium catalyzers to

hydrogenate the H2 and O2 given off by the batteries back into

water droplets. The propeller includes a Kort nozzle which is a shroud around the propeller

which improves its efficiency.

The pressure shell is made from a 0.156 inch wall thickness, 8 inch OD 5052-H32 aluminum

tube welded to a custom machined nose cone and tail section made from 6061-T6 aluminum.

The nose cone includes a housing for a 100,000 candlepower underwater light. I was

responsible for the entire project from the initial concept, through mechanical design,

stress analysis, fluid dynamics analysis, assembly and testing. I did have assistance from

other ME students, primarily for testing, but also for a small amount of the design. The DPV

pressure shell, fore and aft static O-ring seals, and propeller shaft dynamic seals were successfully tested in a pressure simulation

chamber at the Garfield Thomas Water Tunnel to a depth of 300 feet. It has also been used

successfully on numerous dives since then. As a prototype, this device was equivalent, in

features and capability, to the best devices that you could buy at the time. The

hydrostatic pressure test chamber was interesting in its own right, it was a

section cut out of a 16" battleship cannon and could be used to test devices

to a depth of 20,000'.

This project was undertaken as a junior and senior Mechanical Engineering design project at the

Pennsylvania State University. In addition to all of the theoretical courses, there was a

three course sequence where you had to actually design and build something. Normally they

had suggested projects which were less ambitious, but of a scope that would fit within a

single design course. If you had your own ideas they were willing to listen, and they

thought this was a great idea. I, on the other hand, had no idea what I was getting into.

This project would consume my life for the next two years, and I loved it! Designing

the DPV was the highest high I had ever experienced -

this is why I became an engineer!

Diver Propulsion Vehicle

Batteries

and palladium catalyzers

Drive train including electric motor and 4:1 speed reducer,

aft pressure shell, seals, and propeller

|